Archery

Archery is definitely Bhutan’s national sport. Even small villages have an archery range and the distance is way further than I’ve ever seen someone shoot, approximately 145 meters (476 ft), longer than an American football field. Olympic distance is 70 meters (230 ft), which is less than half of a typical Bhutanese setup. The targets are set on the ground and are only about 3 ft tall by 1 ft wide. When we visiting the Trongsa Dzong, there was a competition going on and the opposing team members just hung out on either side of the target when the other team is shooting. They have be to be remarkably accurate archers to be standing so close to an active shooting area. In this competition, they were all using fancy compound bows.

I kept teasing Tenzin that I would be a better shot than he was since I did archery at Girl Scout camp many years ago. When we were in Bumthang, we stumbled upon a tiny setup in the back of the place we had lunch. The target was only 20 meters or so away and we were using simple wooden bows. Tenzin went first and landed an arrow on the target in the first round. My arrows soared right over the top of the target. All four of us kept shooting and not a single other arrow from any of us hit the target. We, nevertheless, had a lovely time mocking each other’s terrible shots and I had to concede that Tenzin was, indeed, a slightly better archer.

We also played a round or two of khuru, basically lawn darts with a similarly small target. Tenzin managed to land a couple darts within the rings, but the rest of struggled with this sport as well.

Angela & Aja Pema, me & Aja Pema, lawn darts & target

Traditional Arts School

While in Thimphu, we took a tour around one of the country’s traditional arts trade schools. Students pick from one of eight pathways they are most interested in studying: mural painting, house painting, sculpture, tailoring, embroidery, woodcarving, mask carving, and metalworking (silver & gold). There are different accomplishments and time commitments based on the course. Mural painting is a six year course ending in a diploma, whereas house painting can be completed in one year ending in a certificate.

The school allows tourists to visit as long as they don’t disturb classes. Many of the students were already quite proficient in their art.

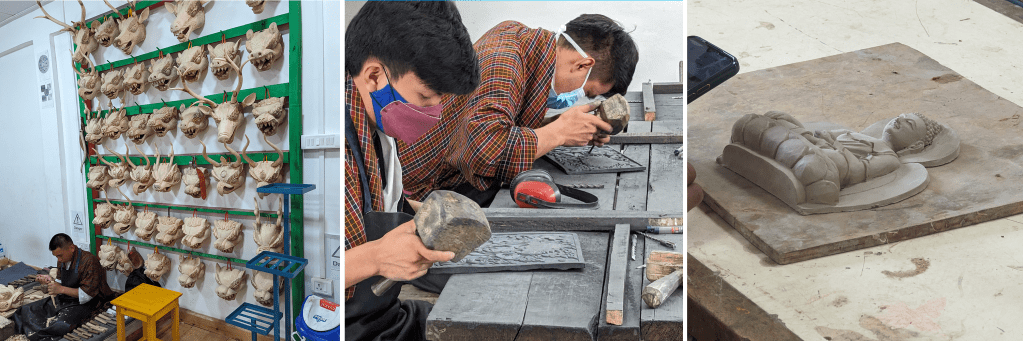

mask carving, stone carving, advanced ceramics

The work of the beginning ceramics class reminded me very much of a typical first-year high school class.

beginning ceramics pieces

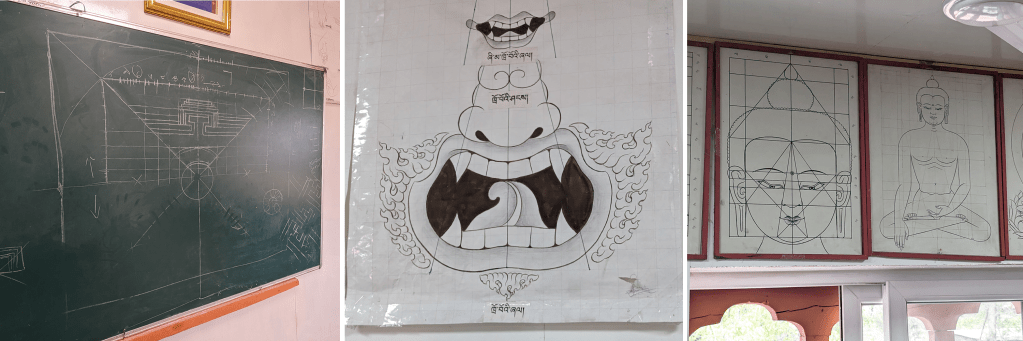

One of my favorite parts was seeing all the math and patterns that were used to teach students proportions. The art in one monastery is very similar to the art in another monastery and this resemblance is possible because of the training received at schools like these. These complex rules and regulations don’t allow for a lot of individuality. On another day, we did visit VAST Bhutan, which is a group that exhibits more modern art by individual artists.

precision art: thangka mandala pattern, wrathful god mouth, Buddha proportions

Jungshi Handmade Paper Factory

This was not my first paper factory tour, but it was my first daphne paper factory tour. The paper from this factory is made from a shrub with white, fragrant flowers. The first step is to remove the bark from the daphne plant and soak it in a giant tub. Afterwards, it is boiled and a crowd of workers tediously removes the unacceptable fibers. They then crush it and make a watery, pulpy mixture. That pulp is piled onto large, rectangular frames and the water drains out. This wet sheet is then transferred to a stack of paper and, somehow, they miraculously don’t stick together. They use a large press to squeeze all of the water out of the entire stack. In the end, one person meticulously moves each sheet of paper over to giant heated easels that speed up the drying process. After about fifteen minutes, the paper is dry. Some paper is sold as is, but the factory also produces books, stationary, and art as well.

removing the paper for, pressing the paper, drying the paper on specially heated boards

Nado Poizokhang Incense Factory

On the other hand, I have never visited an incense factory, so I was super excited to visit one. On the day we went, they weren’t making the dough itself, so we didn’t get to watch that part of the process. The recipe is a secret that has been modified from the original one that is 350 years old that came from a monastery in India. Their regular incense has over thirty ingredients, including juniper, saffron, sandalwood, agarwood, clove, cinnamon, and more. All the ingredients are organic and most are collected by yak herders.

After the dough is mixed, it is extruded through a machine into long coils. Those coils are set on tables and workers cut the coils to size and roll them out evenly. Afterwards, the incense is left to dry on racks, where it is separated into bundles and packaged for sale.

top (l to r): bags of smelly ingredients, rolls of incense dough, dough after it has been extruded

bottom (l to r): rolling and cutting to size, drying incense on racks, bundles of incense

I made a short video to show the steps.